DFP Thermoforming Packaging Machine

Videos of this machine

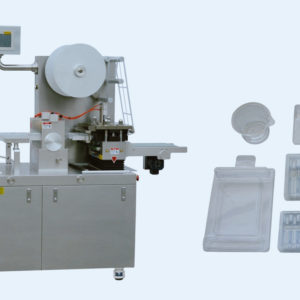

Rigid Film Packaging:

Flexible Film Packaging:

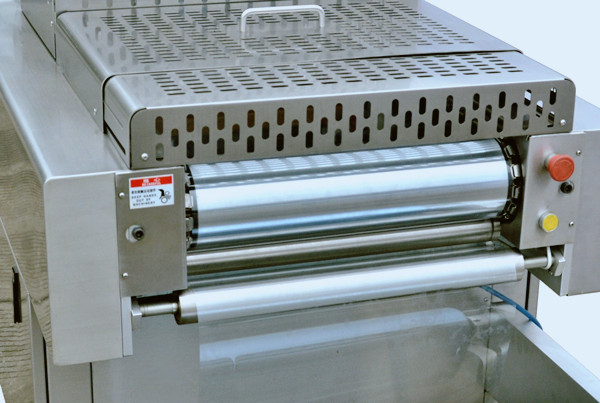

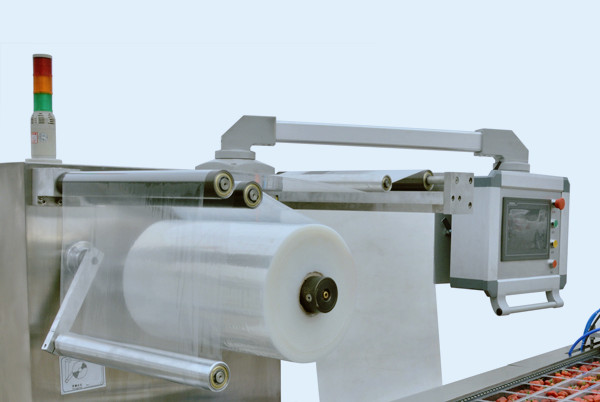

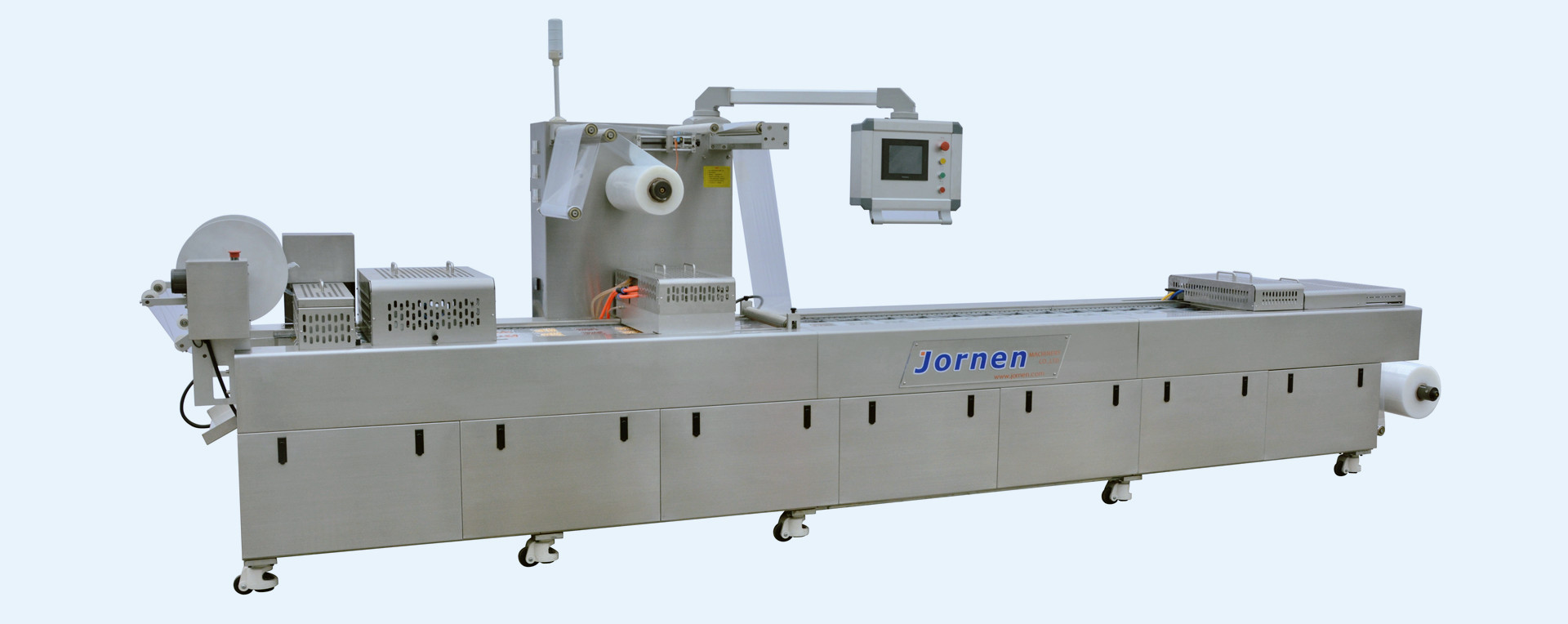

These DFP series of Thermoformer has been designed to pack food and medical products, capable of both flexible and rigid packaging.

They are constructed in corrosion-resistant materials and a full stainless steel structure (AISI 304).

Optional vacuum and gas flushing systems to create (MAP) modified atmosphere packages are available.

Thermoforming Modified Atmosphere Packaging (MAP) is a technique used for prolonging the shelf-life of fresh or minimally processed foods. In this preservation technique, the air surrounding the food in the package is changed to another composition. This way the initial fresh state of the product may be prolonged. It is the shelf-life of perishable products like meat, fish, fruits, and vegetables that will be prolonged with MAP since it slows the natural deterioration of the product. MAP is used with various types of products. The mixture of gases in the package depends on the type of product, packaging materials, and storage temperature.

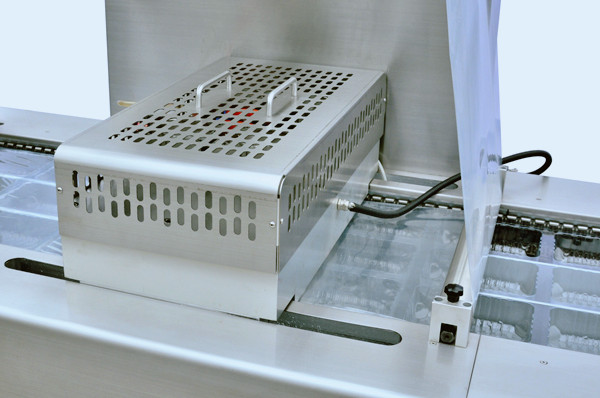

Gallery

Main Technical Parameters

Model: DFP320 DFP420 DFP520

Max. Output: 15/min. 15/min. 15/min.

Flexible Packaging material:

Sealing Material Width: 292mm 392mm 492mm

Forming Material Width: 322mm 422mm 522mm

Rigid packaging material:

Sealing Material Width: 312mm 412mm 512mm

Forming Material Width: 322mm 422mm 522mm

Machine Power: 10Kw 13Kw 20Kw

Machine Dimension: 5100X900X1800 6150X1200X1900 6200X1400X1900

Machine Weight: 1300Kg 1700Kg 2100Kg

See our machines running in pharmaceutical factory

Vacuum Packaging Machine for sweet corn

Thermoforming Packaging Machine for red pepper

Thermoforming Packaging Machine for sea sedge

Vacuum Packaging Machine for cheese

Thermoforming Packaging Machine in New Zealand