Safety Operation Tips of Blister Machine

09/23/2013

- Before turning on the power of the Blister Machine, please read the operation manual carefully to ensure safety.

- The Blister Machine should be operated and maintained by a trained professional. The operator must be skilled in machine structure, operation method, and must comply strictly with operation and safety regulations.

- The Blister Machine should be installed in a location away from heat, humidity, vibration, etc.

- The Blister Machine must be well grounded. A ground sign is provided at the electrical connection point for connecting a ground wire.

- Make sure the voltage of power is in accord with the machine’s power specification.

- At all times, the door of the electric case must be closed, except during maintenance.

- Any electrical fault must be treated by a professional electrician.

- The operator must wear suitable clothes to prevent clothing from becoming entangled in the working parts.

- The operator should never operate the machine under the influence of alcohol, hypnotic medicines, etc.

- When the machine is running, moving or working machine parts should never be touched.

- Before cleaning, maintaining, changing moulds or spare parts, make sure the power is turned off.

- When cleaning the Blister Machine, keep the electrical components in dry condition.

- Note the alarm sign on the machine.

- Personnel must know the location of the emergency STOP switch. In case of emergencies, the STOP button must be pressed immediately.

- If any abnormal situations occur during operation (such as unusual sounds), the machine should be stopped immediately and checked by authorized personnel.

Important Security Guide

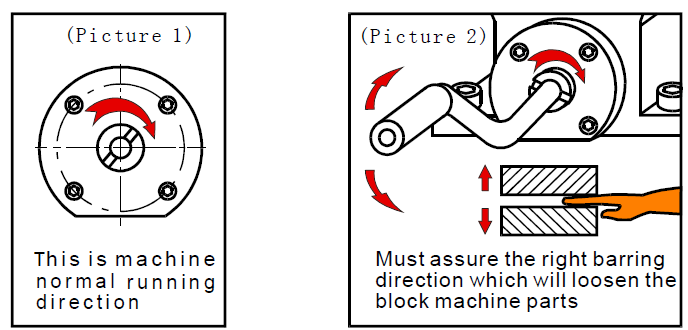

If stuck into this Blister Machine due to fault operation, you must push in the emergency stop button and cut off the electric at once. Calm down and call for help. Then open the manual barring gear door, find barring hole and insert crank handle to slowly run the blister machine to free the block part out of machine. The direction shown on the barring gear is machine normal working direction (as picture shows ) but might not be the right direction which can loosen the injured body part. Only after confirmed the right direction, handle can be turn quickly, otherwise the stuck part will be more stressful and seriously injured. If find in the wrong direction, turn the handle anti previous direction until stuck part free out of machine.