DPP260Ki2 Blister Machine sealing station

DPP260Ki2 Blister Machine sealing station.

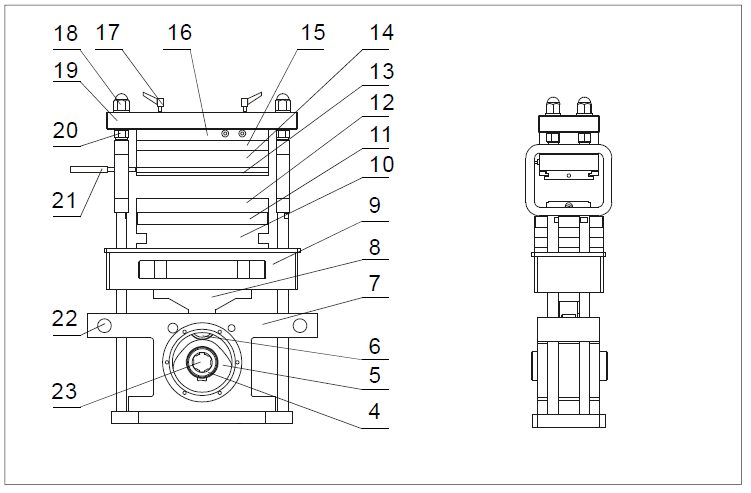

During the Blister Machine is running, the upper sealing mould (15) will be in it’s lowest position driven by heat sealing cylinder, the sealing temperature shall reach 160℃. When lower sealing mould move downward, the upper and lower mould seprate, the formig material (now have blister cavities filled with products) and lidding foil are dragged into the sealing station, lower sealing mould will be rise up driven by sealing cam (5), thus upper sealing mould (15) and lower sealing mould (12) closed, the adhesive side of the lidding material is affixed to the forming material by the heat and pressure, the products are contained between the blister cavities and lidding foil. When lower sealing mould move downward, the sealed web move forward ready for embossing and cutting.

When the Blister Machine stops, the upper sealing mould can rise up automatically, to prevent hot air from getting into the blister pockets, so that medicine (or other goods) effectiveness is preserved.

The schematic diagram of DPP260Ki2 Blister Machine sealing station.