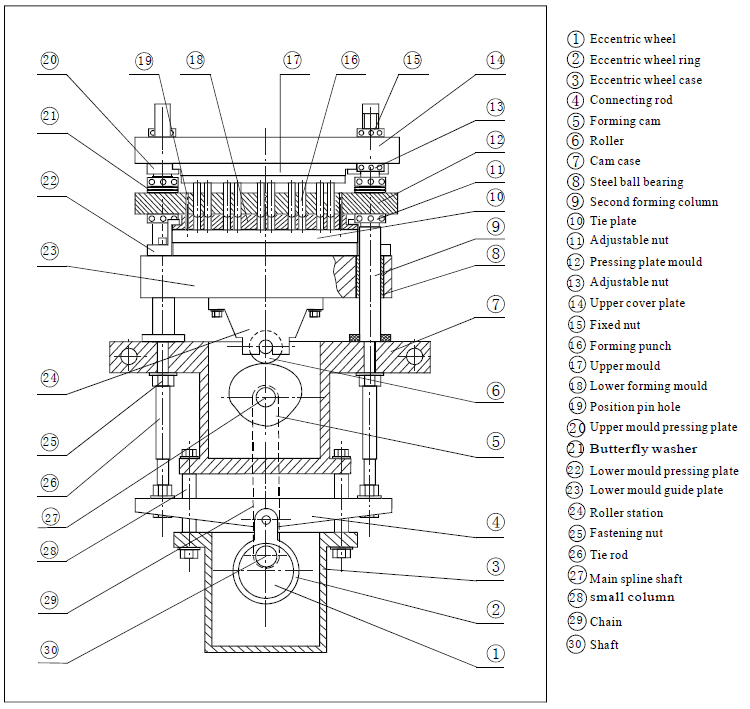

DPP260 Blister Packaging Machine’s cold forming structure

In blister packaging, for some light and moisture-sensitive drugs, the protective properties of the PVC may not strong enough, because of the PVC’s poor barrier against moisture ingress, oxygen ingress and transparent character. In order for better protection and extend product expiration date, Blister Packaging Machine can choose Aluminum/aluminum packaging, also is called the cold forming blister packaging.

In the blister cold forming process, an aluminum film is simply pressed by a plug, similar with “plug-assist” feature in thermoforming blister packaging. The aluminum film will be elongated and maintain the formed shape. The principal advantage of cold forming blister packaging is that the use of aluminum offers a nearly complete barrier for water and oxygen, allowing an extended product expiration date. The principal disadvantages of cold forming blister packaging are: the slower speed of production compared to thermoforming blister packaging; the lack of transparency of the package; and the larger size of the blister card (aluminum cannot be formed with near 90 degree angles).

The following is our DPP series Blister Packaging Machine’s cold forming structure.

When aluminum film is dragged into the forming position in Blister Machine, the forming lower mould (18) will move up by the forming cam (5) to press the plate (12) to fix the aluminum film. Meanwhile the forming plugs (16) which are installed on the upper mould (17) will move down driving by a eccentric wheel (1), then the blisters was formed. After filling, the formed aluminum blisters will then arrive at Blister Machine’s sealing station to seal with lidding aluminum foil, so in blister packaging industry these blisters packaging are also called alu-alu pack.

The cold forming structure of DPP series Blister Machine