DPH series Blister Machine – formed web’s parallel adjustment

DPH series Blister Machine

Adjusting the formed web’s parallel

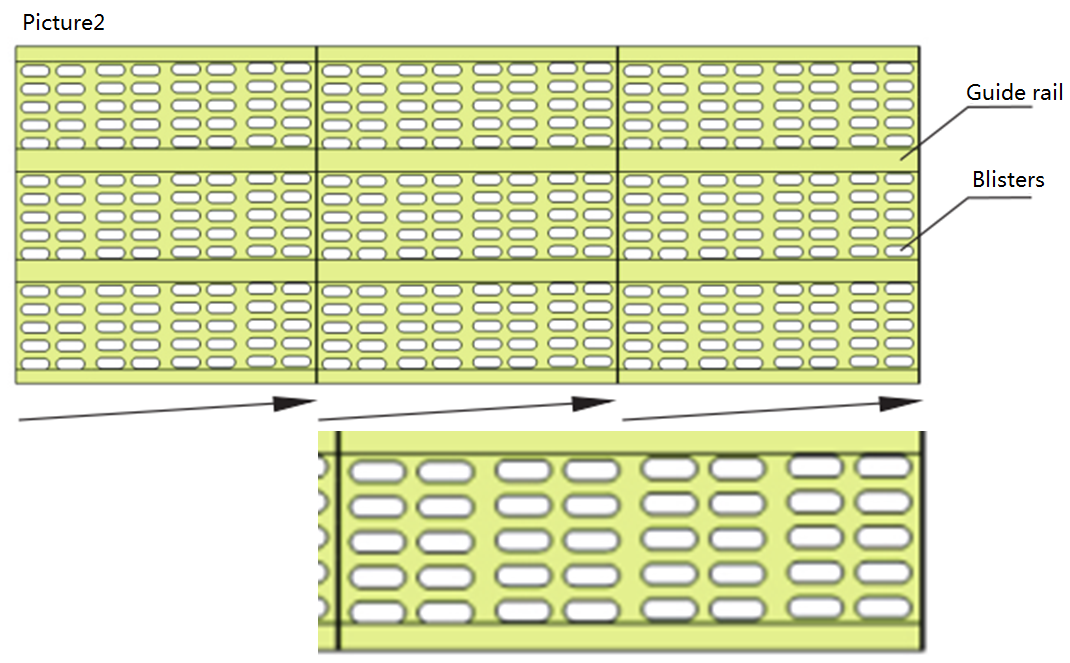

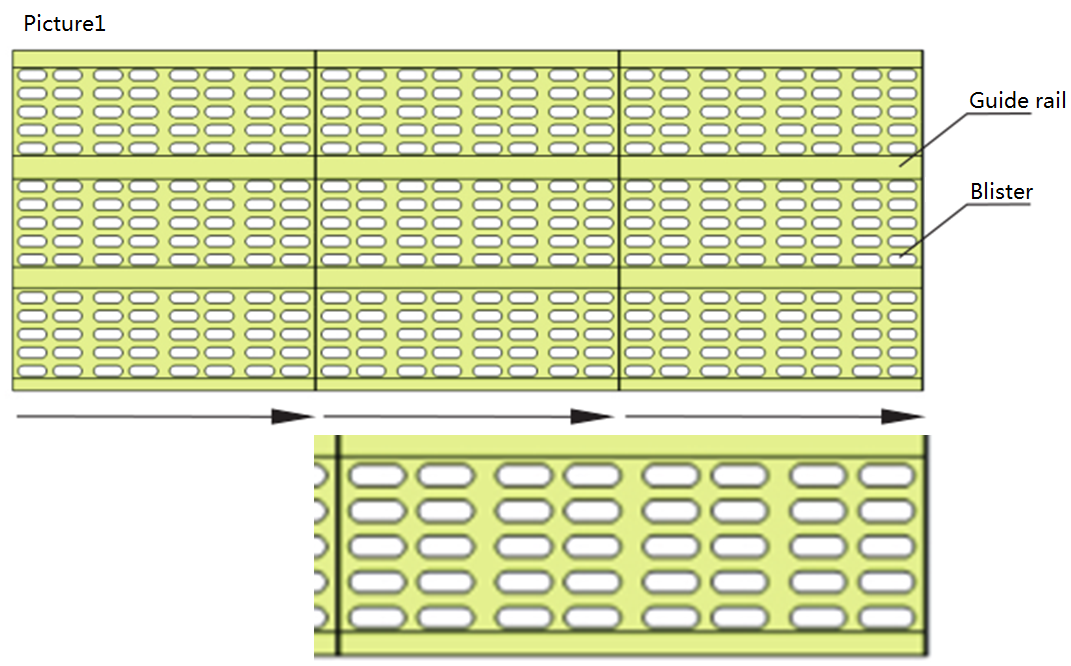

After the forming stating, the formed web is drawn by forming index, then moves to feeding area, under the web there is guide rail to guide the formed web. The blisters should parallel with the guide rail, as picture (1) shows, but due to the mechanical assembly error, the blisters may not parallel with guide rail, as picture (2) shows inclined to left (or inclined to right), this problem normally is cauded by the incorrect position of the lower forming mold, it means the centerline of the lower forming mold is not parallel with the centerline of the guide rail.

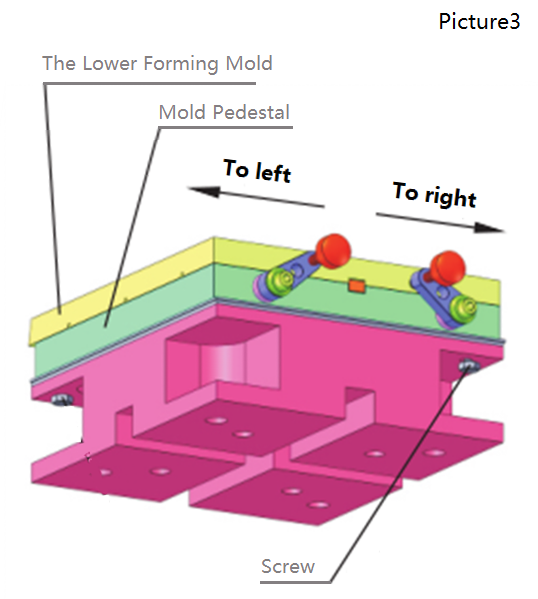

To adjust the position, firstly we need to switch off the machine, remove the stainless steel cover in forming station, under the lower forming mold there is screw (3) see picture (3) , loosen the screw, move the forming mold pedestal (2) to left or right side according to the unparallel condition, after adjustment, slightly fasten the screw then run the Blister Machine again, to examine the newly formed blister, if the blisters is parallel with the guide rail, as picture (1) shows, then fasten the screw (3), put the stainless steel cover back.

blister machine guide rail