Thermoforming Packaging Machine DPP260R

Video of this machine:

The characteristics of Thermoformer DPP260R

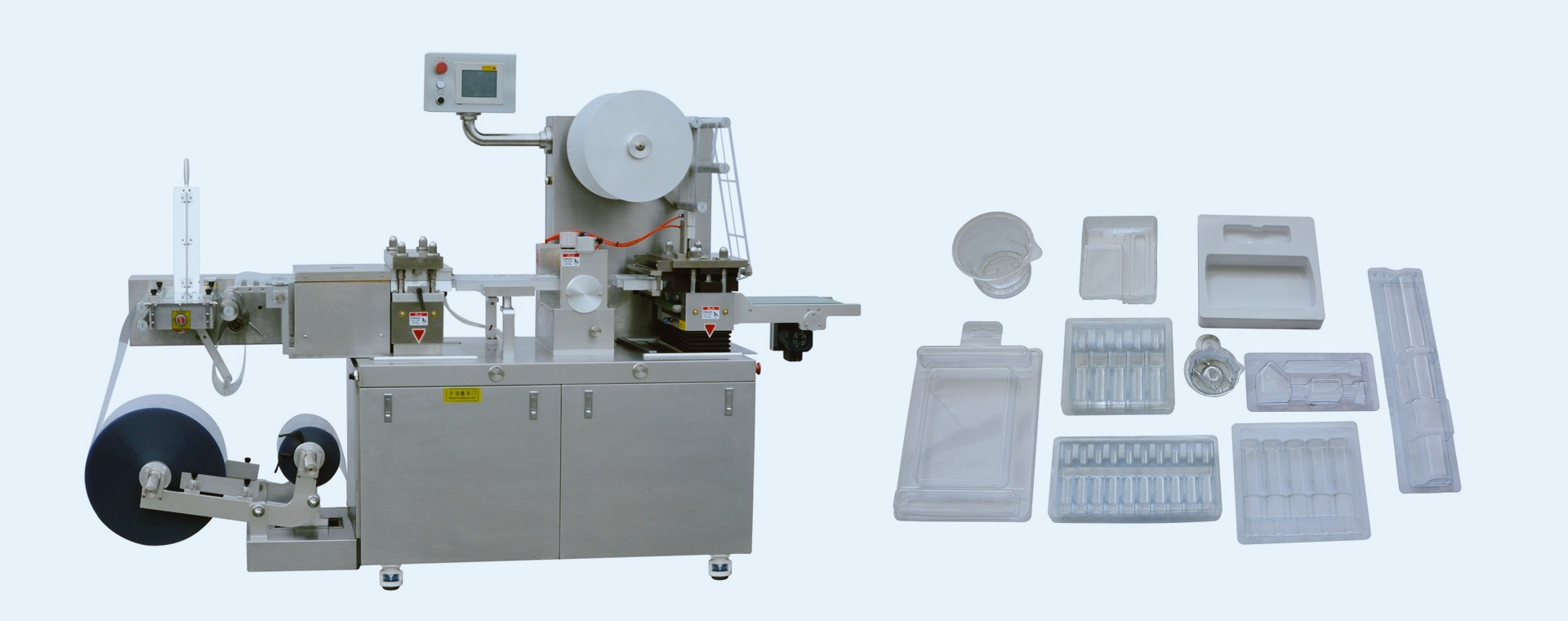

Plastic thermoformed trays, carriers, containers, and cases are wildly used in Pharmaceutical and Medical manufacturers (vials, ampoules syringe, etc.)

Electronic components (USB drive, mouse, batteries, etc.)

Consumer products (cosmetics, toys, food, etc.)

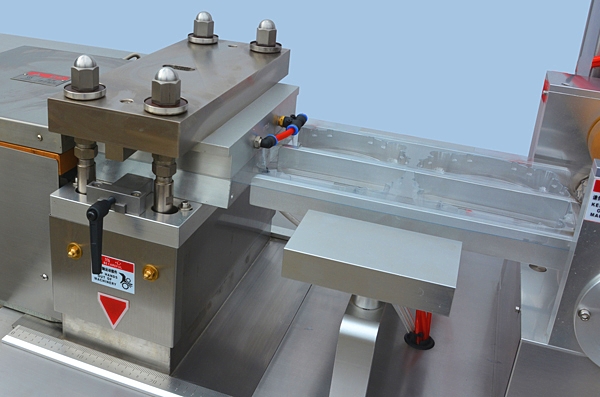

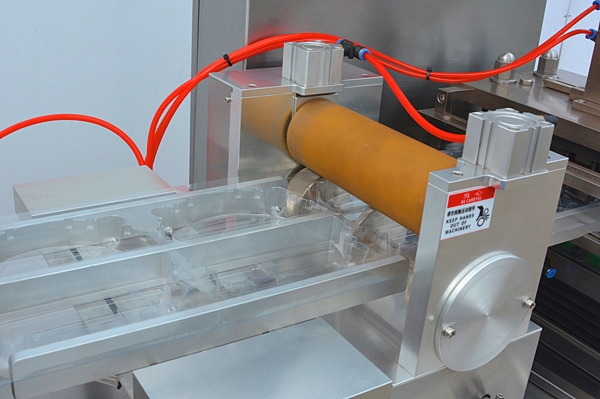

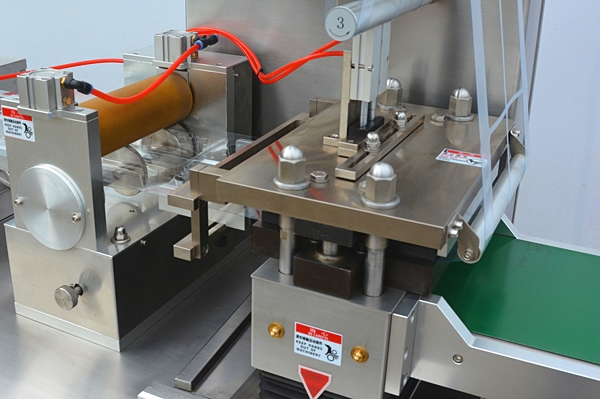

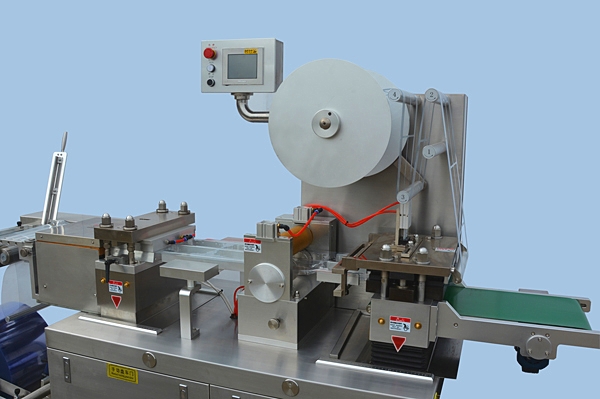

This machine can complete the actions of forming, punching, and discharging the plastic trays automatically. Separation of drive and operating zones and compact structures are in compliance with pharmaceutical GMP and QS requirements.

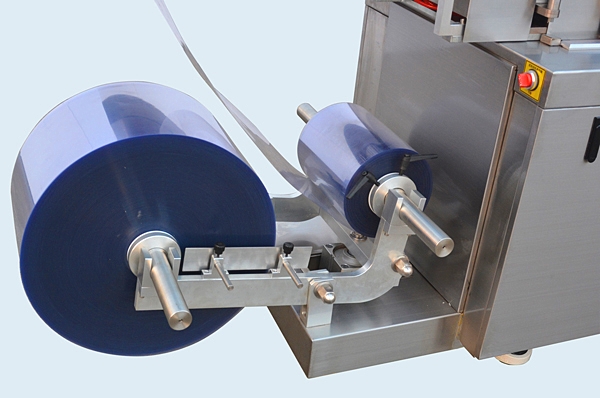

Mold can be custom-designed according to customer’s requirements. Suitable for all kinds of thermoformable plastic material such as PP, PE, PS, PVC, PET, PS, etc.

Plastic thermoformed trays, carriers, containers, and cases are wildly used in Pharmaceutical and Medical manufacturers (vials, ampoules syringe, etc.)

Electronic components (USB drive, mouse, batteries, etc.)

Consumer products (cosmetics, toys, food, etc.)

This machine can complete the actions of forming, punching, and discharging the plastic trays automatically. Separation of drive and operating zones and compact structures are in compliance with pharmaceutical GMP and QS requirements.

Mold can be custom-designed according to customer’s requirements. Suitable for all kinds of thermoformable plastic material such as PP, PE, PS, PVC, PET, PS, etc.

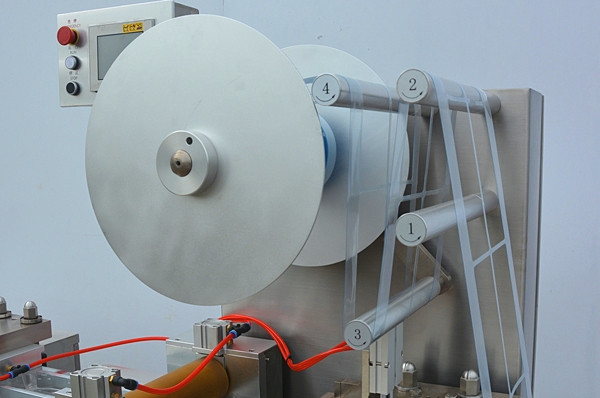

Gallery

Main Technical Parameters

Max. Forming Area: 250x170mm

Max. Forming Depth: 35mm (custom-built: 54mm)

Max. speed: 40punch/min.

Material: Max. width 420mm

Machine Power: 4.5kw

Dimension: 1500×710×2200mm

Weight: 800kg