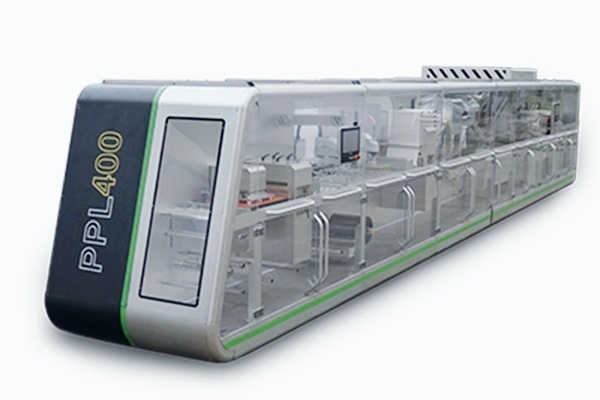

Blister Line PPL400 for Parenteral Products

The video of this Line:

https://youtu.be/mXdyYt5cznA

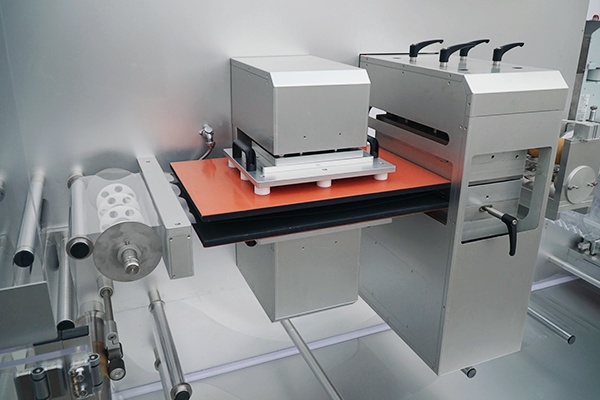

The PPL400 Blister Line is specially designed for the blistering and cartoning packaging of parenteral and oral liquid products. It can package ampules, vials, and syringes in one unit, which is convenient for medical staff to use immediately in emergencies (such as disaster relief sites, battlefields, etc.) to save lives.

Each station of the Blister Line adopts an independent servo drive, which is very convenient for small batches and multiple varieties, and the production mode requires frequent switching of product varieties.

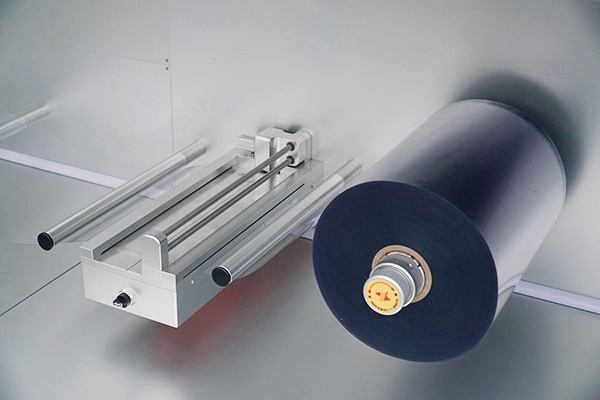

In the blister unit, when the film on the first reel runs out in the blister module, it can automatically connect with the second without interrupting the machine (optional).

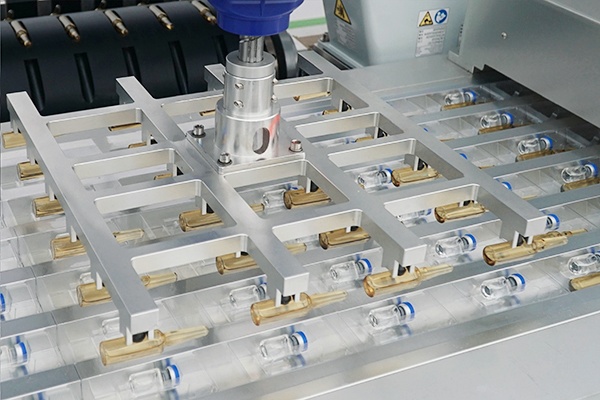

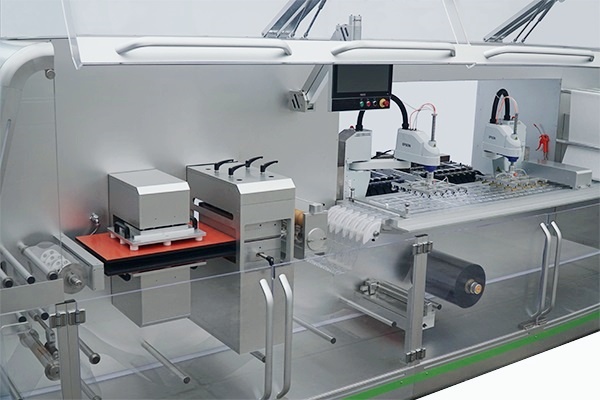

Adopt fully automatic servo robot feeds; the bottle unscrambler first arranges the ampoules, syringes, and syringes neatly, and the robot grabs them and puts them into the Blister pocket; the syringes can be poured into the bin at will, automatically sorted into rows by the system, and transported to the servo robot.

The connection unit of the blister line uses two delta robots. The first robot grabs, adjusts, and puts the blister cards to the variable pitch module; the variable pitch module changes the pitch of the blister cards and sends it to the second robot, and the second robot transfers the blister cards to the cartoning unit. The connection unit is very flexible, and one carton can be set to hold one or more blister cards at will; the compact design saves space.

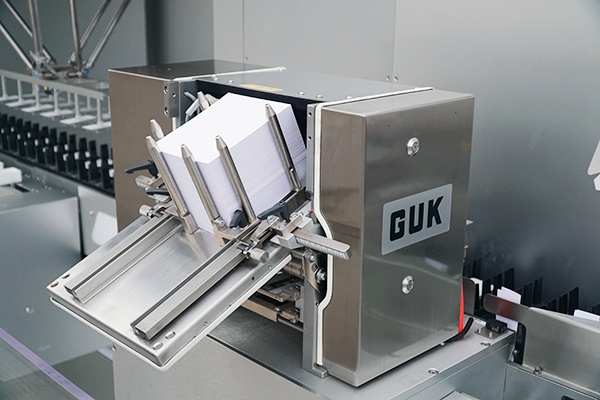

The cartoning unit adopts a continuous motion structure, which is efficient and stable.

Capable of all standard closure systems for cartons from tuck-in to hot melt.

Automatic carton loading is optional, carton consumption is high-speed at high speed, and frequent manual loading is required.

The whole line adopts a balcony structure, and the operation and driving areas are isolated to avoid cross-contamination and facilitate daily cleaning.

The protective door of the entire line optimizes ergonomics and adopts an upward-flipping opening structure; when opened, it fully utilizes the upper space to provide operators with an open, barrier-free front operating space.

Fully enclosed with an innovative design, the contour lines are round and elegant. It perfectly combines machinery and art.

-300x300.jpg)