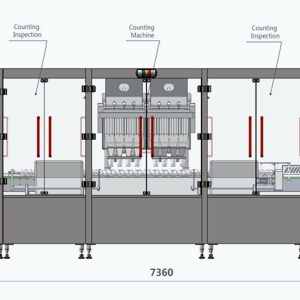

Compact Counting Line (120 bottles/min)

Compact Counting Line (120 bottles/min)

Videos of this these Machines:

https://youtu.be/IKJ0qDjokDI

https://youtu.be/ZciLbhjSjWs

https://youtu.be/MIKmniYNars

https://youtu.be/wpq_5a7q_Lo

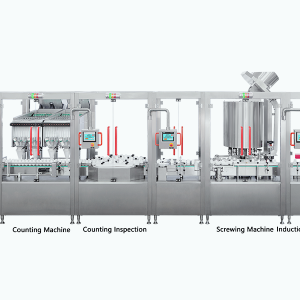

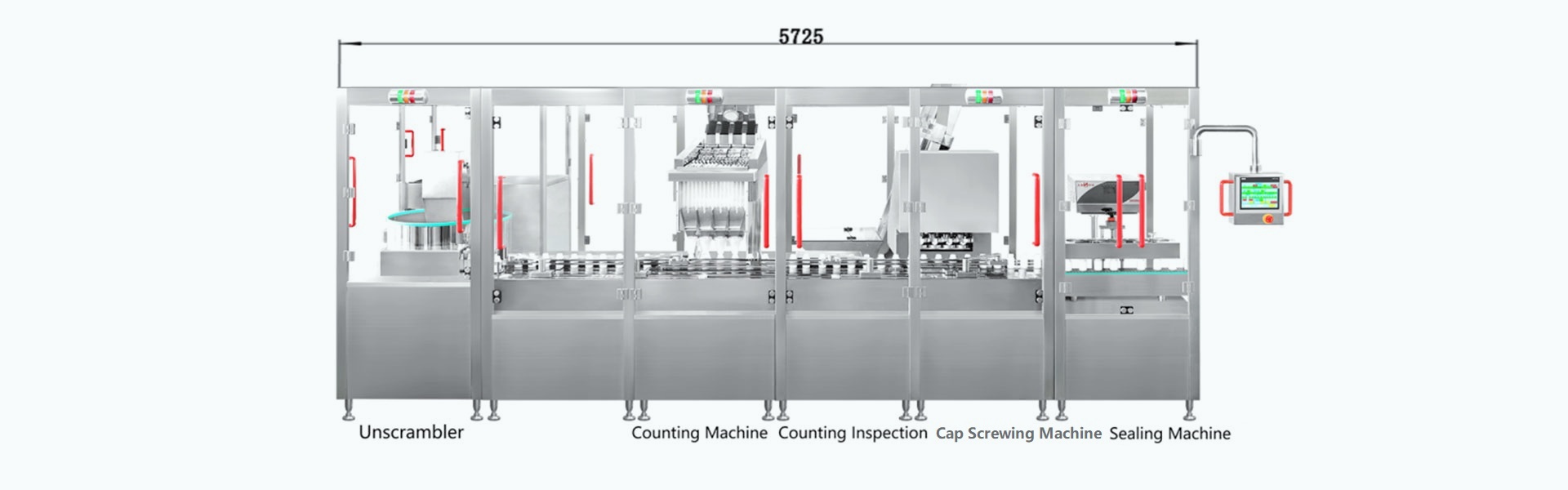

● This compact counting line adopts an integrated and modular design, including Unscrambler+Counting+Double Validation Function for Counting and Filling System+Capping+Sealing Machine. The total length of the line is less than 6 meters, which is reduced by half compared to ordinary counting lines. It can help enterprises save about 50% of equipment space and is suitable for upgrading and renovating old workshop production lines.

● The entire system, including each equipment unit, can be separated for convenient transportation and installation.

Adopting a tooth-shaped synchronous bottle-moving system smooths the entire process without shaking, impacting, or overturning. The tooth-shaped synchronous bottle-moving system, bottle specifications, and the number of drugs filled in the bottle all have formula storage functions, which can be called up with one click when changing specifications and are intelligent and efficient.

● The compact counting line adopts CCD intelligent visual counting and double validation function for the counting and filing system to control the unqualified counting rate within 1/50000.

● The CCD intelligent vision system has an automatic fill light adjustment function and strong dust prevention ability; even for tablets with large dust, it can ensure counting accuracy. Realized the precise counting for a long time in a strong dust environment.

● It adopts a claw-type torque control capping system, suitable for various bottle caps, such as CRC pressure capping, gold-plated caps, and anti-theft safety caps. This system ensures the bottle cap is tightened without damaging the cap and body.

● Optional isolator can realize the packaging of anti-tumor drugs.

1. Automatic Unscrambler

High speed, high compatibility

Suitable for round bottles, square bottles, and other plastic bottles

Large capacity storage bin

Save space

2. Machineg Machine

Applicable to various shapes and specifications of medicines

Approachable screen display and intelligent menu

A high-resolution CCD counting sensor makes counting accurate.

It has a strong ability to resist powder, it can automatically adjust sensitivity, and it will automatically alarm and stop when an exception occurs.

It automatically inspects the air cylinder and air pressure parameters and automatically alarms and stops when an exception occurs.

Constant feeding device and multi-layer pre-count system are adopted to ensure its high speed and stable operation

3. Counting Inspection

To obtain the medicine’s net weight, two individual check weighers were fixed before and after the counting &Machineg machine.

Discriminant accuracy reaches as high as ±30mg to guarantee its high precise detection for medicine filling more and less.

4. Machineg Machine

It has the function of automatic cap lifting, cap neatening, and cap screwing.

It is suitable for various bottle caps, such as CRC pressure capping, mirror caps, anti-theft safety caps, etc.

Claw design, vertical cap removal, and capping

Torque control can significantly improve the qualified rate of screwing caps

No damaged bottles, no damaged caps in the process of screwing caps

Modular design, quick specification change, no need for adjustment, intelligent and efficient, easy for ordinary operators

5. Machineg Machine

Adopting air-cooled non-contact sealing technology, there is no need to change or add water or worry about bacterial growth, which meets FDA requirements.

Completely closed shield measures, free of electromagnetic pollution, safe and steady operation

Detection device of no aluminum foil, double aluminum foil, and inversed aluminum foil

Automatic alarm system for over-temperature,under-voltage, over-current

By adopting two power levels of coils, the sealing efficiency is higher, and the application range is more expansive.