Bottle Packing Line

Bottle Packing Line

Videos of this these Machines:

https://youtu.be/IKJ0qDjokDI

https://youtu.be/ZciLbhjSjWs

https://youtu.be/MIKmniYNars

https://youtu.be/wpq_5a7q_Lo

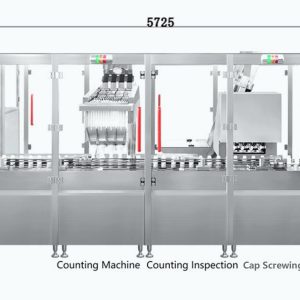

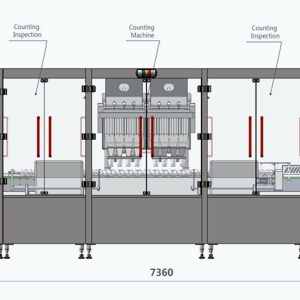

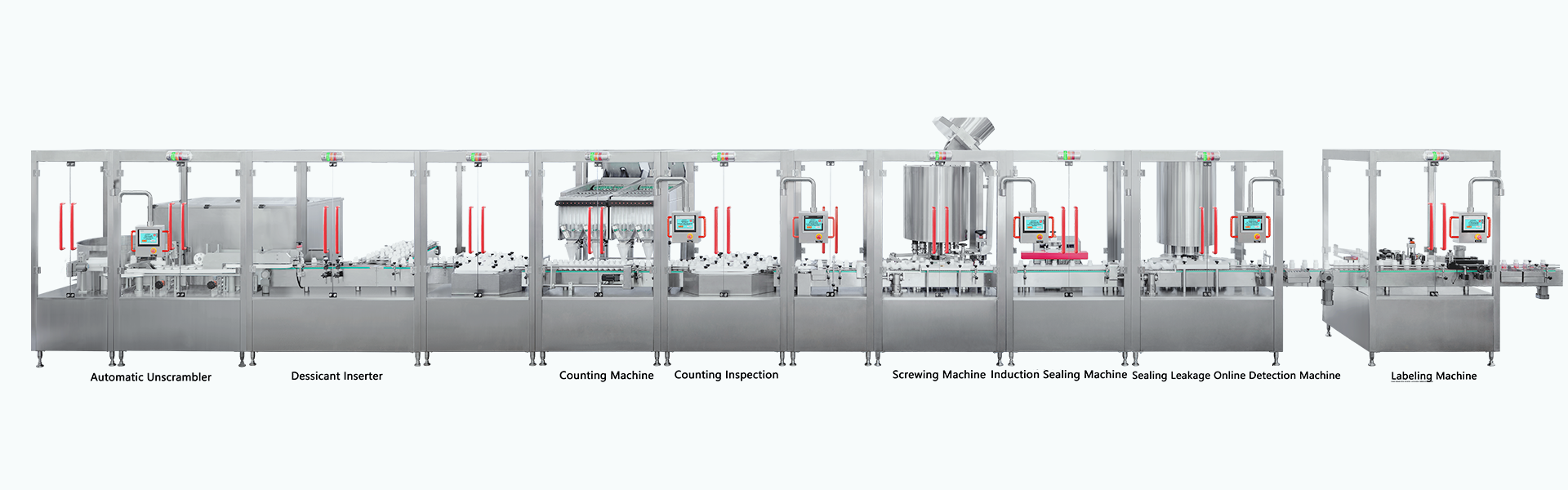

● Fully automated bottle packaging line, including equipment: bottle trimmer, corking machine, granule counting machine and granule counting re-verification system, capping Machine, aluminum foil sealing Machine and sealing leakage in-line detection machine, labeling Machine, etc.

● The production process of the products can meet the requirements of GMP, FDA, and other specifications.

● According to the customer’s actual needs and site conditions, it can meet different capacity requirements and be optional for different equipment combinations to achieve customized services.

● Adoption of compact design improves space-capacity ratio and controls GMP operating costs.

● The combination of a grain counting machine and missing grain detector, the combination of an aluminum foil sealing machine and sealing leakage in-line detector, and other products with detection functions included in the bottle packaging line can reduce the quality risk in the production line and provide users with a more advanced, stable, and reliable bottle packaging line.

1. Automatic Unscrambler

High speed, high compatibility

Applicable to plastic bottles of all shapes, such as round, square, flat, oval, etc.

Large capacity storage bin

Static electricity and dust-removing functions are available on the Machine.

2. Desiccant Inserter

The precise positioning of the cursor and the checking of the desiccant bag length determination system ensure that the desiccant will not be cut through.

The Machine will alarm and stop if desiccants do not fall into bottles.

The Machine will alarm in time when it runs out of desiccants.

3. Counting Machine

Applicable to various shapes and specifications of medicines

Approachable screen display and intelligent menu

A high-resolution CCD counting sensor makes counting accurate.

It has a strong ability to resist powder, it can automatically adjust sensitivity, and it will automatically alarm and stop when an exception occurs.

It automatically inspects the air cylinder and air pressure parameters, alarming and stopping when an exception occurs.

Constant feeding device and multi-layer pre-count system are adopted to ensure its high speed and stable operation

4. Counting Inspection

Two individual check weighers were fixed before and after the counting & filling Machine to obtain the medicine’s net weight.

Discriminant accuracy reaches as high as ±30mg to guarantee its high precise detection for medicine filling more and less.

5. Screwing Machine

It has the function of automatic cap lifting, cap neatening, and cap screwing.

It is available for various screw threads of caps.

Torque control can significantly improve the qualified rate of screwing caps

No damaged bottles, no damaged caps in the process of screwing caps

Cap-screwing at high speed, with steady performance, easy to operate

6. Induction Sealing Machine

Completely closed shield measures, free of electromagnetic pollution, safe and steady operation

Detection device of no aluminum foil, double aluminum foil, and inversed aluminum foil

Automatic alarm system for over-temperature,under-voltage,over-current

Detection device for sealing temperature

Sealing with high-efficiency

7. Sealing Leakage Online Detection Machine

High-speed negative pressure detection

Speed:200 bottles/min

Appropriate for high-speed online detection of the sealing quality of aluminum foils on various types of bottles or can containers.

8. Labeling Machine

Record the label length intelligently, and there is no need to set it manually.

Applicable to round bottles

Miss printing and missing labeling will be rejected automatically.

Remain label numbers can be set and reminded.

Code tagging(code spraying, laser code) and code reading(one-dimensional, two-dimensional code) systems are optional units.