DPP260 Blister Machine forming heating mechanism

DPP series Blister Machine forming heating mechanism

The device can heat and intenerate the material(PVC). After the material(PVC) enter into the forming station, the blisters are formed by compressed air. The working principle as following:

First, through the control interface set the forming temperature and compressed air blow time.

Different forming material ( PVC) have different thickness. According to differences of forming shape, size and deepness, the machine need different working temperature. Common material (PVC) of 0.25mm thickness, setting the temperature at 105-110℃ usually.

When the Blister Machine running the lower heat pate moving up and down, it makes the upper and lower heat plate open and close repeatedly. When the upper and lower heat plate closed, the material (PVC) is intenerated. When the upper and lower heat plate open, the material (PVC) is dragged to the forming station.

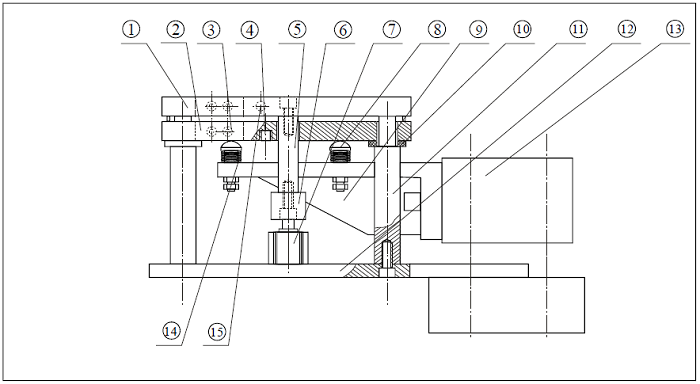

The schematic diagram of DPP series Blister Machine heating mechanism